Why Your Powersports Engine Break-In Is Essential

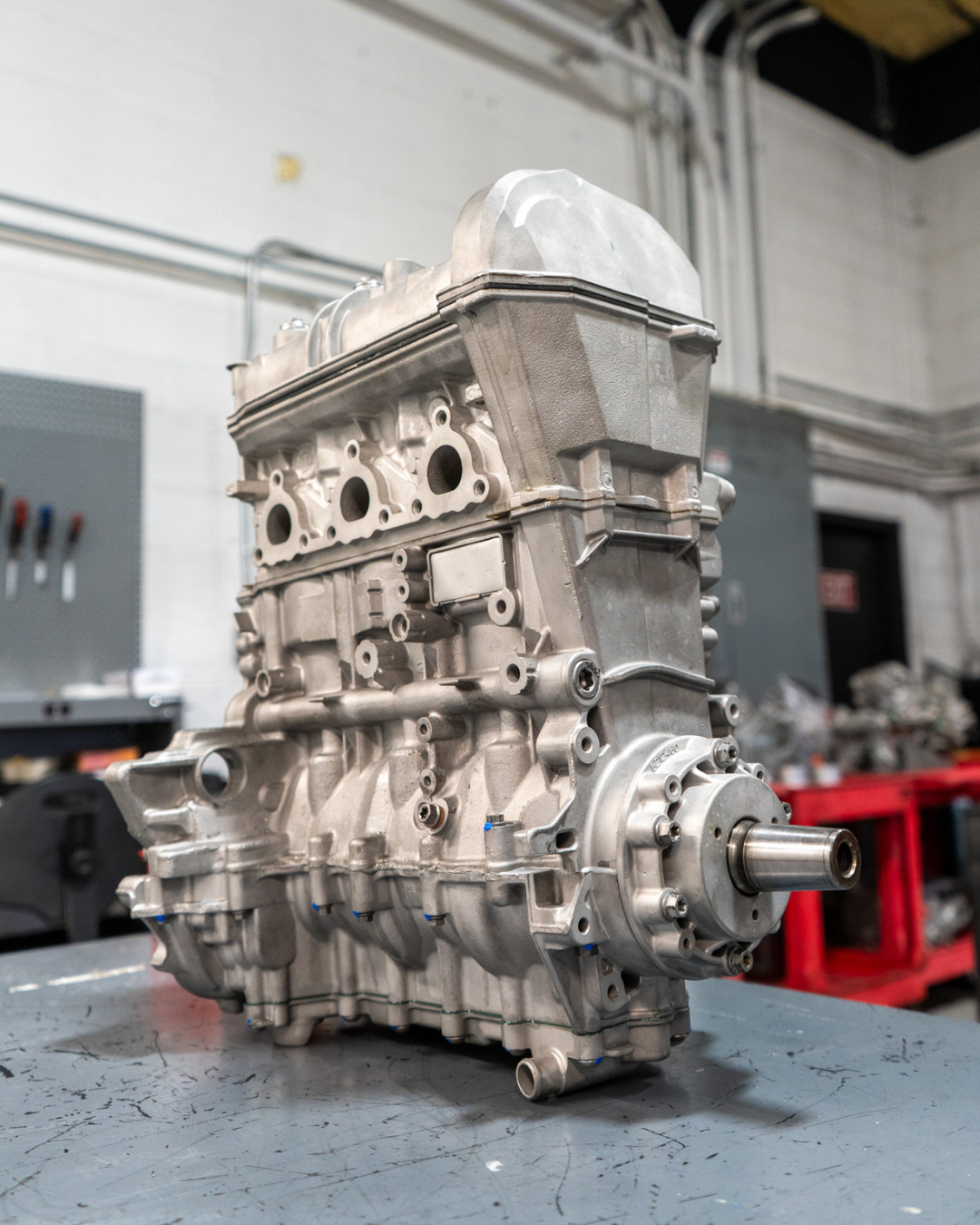

When you install a new or remanufactured UTV, ATV, snowmobile, or watercraft engine, one of the most critical steps in ensuring long-term reliability and performance is the break-in process. With our years of experience and expertise at REV6, we’ve seen time and time again that proper engine break-in makes the difference between a dependable machine and one plagued by early wear, low performance, or even premature failure.

In this article, we’ll break down why break-in matters, what happens during the process, and how to do it the right way.

The Consequences of Improper Break-In

Failing to break in a new powersport engine properly can lead to a number of issues that shorten its lifespan and reduce performance. Here are some of the most common problems we see when break-in is neglected or done incorrectly:

- Piston Ring Sealing Failure: If the rings don’t seat properly against the cylinder walls, the engine may experience oil consumption, blow-by, and carbon buildup on the pistons. This results in lower compression and reduced power output.

- Bearing Wear and Failure: Bearings need to wear in gradually. Without a proper break-in, they can develop uneven wear patterns, increasing the risk of main or rod bearing failure.

- Camshaft and Valvetrain Wear: New camshafts and valve buckets must be broken in together. Without this initial wear-in period, components can create excess friction, shedding metal debris that circulates through the engine and damages other parts.

In short, skipping or rushing break-in leads to avoidable wear that compromises performance and reliability over time.

The Benefits of Proper Engine Break-In

Breaking in your UTV, ATV, snowmobile, or watercraft engine correctly provides long-term advantages that start from the first hour of use:

- Longer engine life

- Improved ring sealing and compression

- Better oil control and reduced consumption

- Smoother camshaft and bearing operation

- Higher and more consistent performance

These benefits are directly tied to how well components like rings, bearings, and valvetrain parts wear into their correct operating surfaces.

What’s Actually Happening During Break-In

Let’s take a closer look at the mechanics of the break-in process:

- Piston Rings: New rings must wear into the cylinder bore to create a full and uniform seal. At first, microscopic gaps exist between the rings and the cylinder wall. Controlled wear during break-in allows those surfaces to fully mate, minimizing blow-by and oil loss while maximizing compression.

- Bearings: Main and rod bearings must gradually conform to the crankshaft and connecting rods. Early wear is normal and necessary to establish proper oil clearance and load distribution.

- Camshaft and Buckets: New camshaft lobes and valve buckets work hard during the initial run time to establish smooth contact. Without break-in, these parts can wear unevenly or shed metal that circulates through the engine.

- Heat Cycling: As the engine heats up and cools down during break-in, components expand and contract. These heat cycles help stabilize internal parts, relieving stress and allowing materials to seat properly.

REV6 Break-In Recommendations

REV6 provides recommended break-in oils specifically designed to support this process. We advise against using full synthetic oil during initial break-in, as it may be too lubricative and prevent proper ring seating.

General guidelines include:

- Avoid full throttle or extended high-RPM operation during the first 10–20 hours of run time.

- Do not hold the steady throttle for long periods. Vary engine speed and load frequently to encourage full ring seating and even wear.

- Run multiple heat cycles. Allow the engine to warm up fully, cool down, and repeat. This helps all internals stabilize under real-world thermal conditions.

Break-in should be completed under controlled conditions, and always according to the specifications for your specific build. REV6 includes detailed break-in instructions with every engine, and we’re always available to answer questions about your application.

Final Thoughts

A successful powersport engine build doesn’t end at assembly—it continues through break-in. Taking the time to properly break in your engine ensures that every component functions as intended, resulting in better performance, greater reliability, and longer service life.

Need assistance or more info? Contact Us today. For additional details, check our Warranty Policy or FAQ. Learn more in our Engine Rebuild Kit Guide—custom kits available.

Find additional engine tips and procedures by subscribing and following us on social media: