Tips for UTV & ATV Engine Upgrades

Building Power That Holds Up

When you’re miles from the trailhead or buried axle-deep in a mud hole, “stock” doesn’t mean dependable. Whether you’re pushing a Polaris RZR harder than it was ever intended or working a Can-Am Defender day after day, your engine is only as strong as its weakest internal part.

At REV6, we tear down hundreds of engines and transmissions every month. Patterns show up fast. Certain components fail early. Certain tolerances don’t hold once heat, load, and RPM stack up. After seeing the same failures over and over, the fixes stop being theory and start becoming standard practice.

If you’re ready to move past bolt-ons and focus on upgrades that actually survive hard use, these are the internal changes that make the biggest difference.

1. Forged Crankshafts: Where Strong Builds Start

Where stock fails:

OEM crankshafts are one of the first weak points once tire size, vehicle weight, or sustained RPM increase. Cast cranks don’t tolerate vibration and shock loading for long, especially in machines that see aggressive riding or heavy work.

The fix:

A forged performance crankshaft.

Forged cranks handle heat and load without flexing or cracking. They stabilize the rotating assembly and prevent failures that usually take the rest of the engine with them.

Shop takeaway:

If you’re rebuilding a Polaris 900 or 1000, reusing or “patching” a worn crank is a gamble. Starting with a REV6-spec forged crank tightens tolerances and gives the bottom end a fighting chance to last.

2. Pistons & Rings: Compression That Works for You

Where stock comes up short:

Factory pistons are built for average use. Once riding turns aggressive or loads increase, throttle response and torque suffer.

The fix:

Forged pistons matched with the correct ring package.

Forged pistons handle heat better, resist skirt collapse, and allow tighter clearances. When compression is set correctly, you gain torque and response without sacrificing reliability.

Pro insight:

On naturally aspirated builds, properly set compression delivers noticeable gains without adding complexity or stress elsewhere in the engine.

3. Valve Guides & Heat Control: Keeping Power Consistent

The issue most riders miss:

Heat kills engines slowly. Weak valve guide material leads to poor seating, inconsistent airflow, and power loss as temperatures rise.

The fix:

Upgraded bronze or manganese valve guides.

These materials manage heat far better than stock guides. Valves stay aligned, sealing stays consistent, and power doesn’t fall off halfway through a long ride.

4. Bearings & Transmission Internals: Fixing Failures Before They Start

Where things go wrong:

Mud, dust, and torque loads beat up internal bearings. Once a bearing wears or moves, damage spreads fast.

The fix:

High-load bearings built to hold tolerance under abuse.

The REV6 approach:

We use bearings designed to stay put and reduce internal friction. Less friction means more usable power and longer service life for both engines and transmissions.

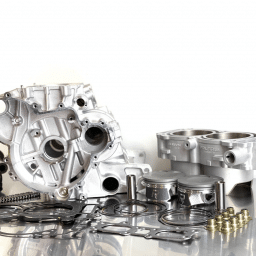

DIY Rebuild Kits vs. Complete Engine Rebuilds

REV6 supports both sides of the rebuild world. Some customers want parts they can trust on their own bench. Others want a finished engine built correctly without guessing. The difference isn’t who turns the wrench — it’s how the internals are handled.

If you’re still deciding which direction makes sense, the engine rebuild kit guide breaks down the options clearly.

DIY Rebuild Kits for Shops, Mechanics, and Experienced Builders

REV6 rebuild kits are built for people who understand measurements, clearances, and proper assembly. These aren’t generic gasket boxes. Each kit uses the same internal components we install in our full engine rebuilds.

- Forged pistons

- Heavy-duty bearings

- Precision-matched seals and internal components

If questions come up during planning or installation, the REV6 FAQ covers fitment, break-in, and common rebuild concerns.

Complete Engine Rebuilds for Riders Who Want It Done Right

For customers who want a finished engine without risk, REV6 offers complete in-house engine rebuild services. Your core is fully torn down, inspected, machined as needed, and rebuilt by experienced technicians.

If you’re new to the process, the REV6 Help Center walks through shipping, core handling, and what to expect from start to finish.

Why Internal Quality Matters

Whether you’re installing a rebuild kit or ordering a complete engine, internal quality determines how long the machine lasts. Correcting known OEM weak points during the rebuild often results in engines and transmissions that outlive the originals.

Before committing, it’s worth reviewing the REV6 warranty coverage so you understand how parts and rebuilds are supported after installation.

Ready to Move Forward?

Waiting for a failure is the most expensive way to learn about engine internals. Whether you’re planning a DIY rebuild or considering a complete engine rebuild, REV6 has the parts, experience, and process to support the job.

Build it once. Build it right. Get back to riding.